Non Destructive Testing

Ultrasonic Testing

Ultrasonic testing is often performed on steel and other metals and alloys. It is used in many industries including steel and aluminium construction, metallurgy, manufacturing, aerospace, automotive and other transportation sectors. ULTRATECH ENGINEERS provides

- UT with recording

- UT with B-scan

- Ultrasonic Thickness Measurement

Radiographic Testing

Radiographic Testing (RT) involves the use of either x-rays or gamma rays to view the internal structure of a component. In industry, RT is often used to inspect machinery, such as pressure vessels and valves, to detect for flaws. ULTRATECH ENGINEERS provides four types of Radigraphy.

- Gamma Radiography

- Cobalt Radiography

- External X-ray Radiography

- Internal X-ray Radiography

Magnetic Particle Testing

Magnetic particle Testing (MPT) is a process for detecting surface and shallow subsurface discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and some of their alloys. The process puts a magnetic field into the part.

To identify a leak, ferrous particles, either dry or in a wet suspension, are applied to a part. These are attracted to an area of flux leakage and form an indication, which is evaluated to determine its nature, cause, and course of action, if any. ULTRATECH ENGINEERS provide

- Yoke Type MPT

- Prod Type MPT

- Bench Type MP

Visual Testing

Visual testing (VT) is the oldest and most common NDT techniques. It is typically the first step in the examination process to inspect a variety of product forms including castings, forgings, machined components and weld elements, according to the NDT Training & Test Center.

Compared to other techniques, visual testing is low in cost and easy to apply, and often eliminates the need for further types of testing. Some of the industries that use VT include structural steel, automotive, petrochemical, power generation, and aerospace. ULTRATECH ENGINEERS Provides

- Videoscopy Visual Testing

- Boroscopy Visual Testig

- Fibroscopy Visual Testing

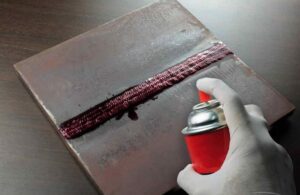

Penetrant Testing

Penetrant testing (PT), is a widely applied and low-cost inspection method used to check surface-breaking defects in all non-porous materials (metals, plastics, or ceramics). The penetrant may be applied to all non-ferrous materials and ferrous materials.

PT is used to detect casting, forging and welding surface defects such as hairline cracks, surface porosity, leaks in new products, and fatigue cracks on in-service components. ULTRATECH ENGINEERS provides

- Visible Penetrant Testing

- Fluorescent Penetrant Testing

- Water washable Penetrant Testing