Destructive Testing

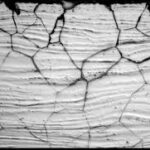

Intergranular corrosion (IGC)

Intergranular corrosion (IGC) testing is the only corrosion test performed as a standardized pre-delivery test. Strauss, Huey and Streicher are the common test methods. They are carried out as a rule on samples from finished tubes in the as-delivered condition or on material that has been sensitized, i.e. heated in the critical temperature range in a furnace or by welding.

Impact testing

Impact testing measures the material’s ability to absorb energy when fractured at high velocity. This gives an indication of the ‘toughness’ of the metal and two methods are usually employed for impact testing, Charpy or Izod.

Tensile testing

Tensile testing, or tension testing, is used to determine the behaviour of the metal when it is being pulled. Tensile testing can measure yield strength, proof strength and ultimate tensile strength. We have a range of tensile testing machines and can apply loads from a few newtons to 1,000 kilo newtons, and test up to 600°c.

Hardness testing

Hardness testing assesses the impact of the metal or alloy to permanent indentation, and the depth or size of the indent is measured to determine a hardness value. There are several different hardness tests and we use the Brinell, Vickers and Rockwell methods.

Bend Testing

Bend testing is used to measure stiffness and yield properties of a material or component. Bending a sample can determine how a material reacts under pressure. This test can help determine a materials ability to resist cracking or other surface issues as force is applied during one continuous bend.

Positive Material Identification (PMI)

Positive Material Identification (PMI) is the analysis of a metallic alloy to establish composition by reading the quantities by percentage of its constituent elements. Typical methods for PMI include X-ray fluorescence (XRF) and optical emission spectrometry (OES). PMI is used to analyse and identify material grade and alloy composition for quality and safety control.

Chemical Test and Analysis

> Chemical Analysis for alloys like carbon steel, low/high alloy steel, tool steel, all types of stainless steel grades, free cutting steel, aluminium base metal etc.

> Spectro analysis of copper alloys e.g. pure copper, brass, bronze, gun metal, Cupro-Nickel etc.

> Chemical Analysis of Nickel base metals & alloys i.e. Nickel-Copper alloys(Monels), Nickel-Chromium Alloys, Nickel base other alloys, Nickel-Fe alloys etc.

> Positive Material Identification at lab & site by XRF method

> Positive Material Identification (chemical analysis with carbon) at site by mobile/portable spectrometer.

MECHANICAL TESTING

> Tensile test at Room temperature.

> Tensile test at elevated temperature up to 800°C.

> Various bend tests like root bend, face bend, side bend, reverse bend, parent metal bend, double bend, and rebend.

> Flattening, Flaring, Drift Expansion, Reverse flatting

> Pullout test of mock-up joints of tube sheet joints

> Cold crushing, Bulk density & Permanent linear change test of refractions

> Charpy ‘V’ Notch Impact test (+100 to -196°C)

> Dimension measurement test

> Proof load of bolt

> Wedge load of bolt and nut

> Full-size braking of bolt

> Proof Load of Nut e Rockwell Hardness

> Brinell, Vickers & Rockwell Hardness

> Micro Vickers Hardness

> Macro test of welded sample

> Unit weight measurement

> Shear test of bolt

> Rockwell, Vickers Hardness

> Re-tempering test of fastener

METALLORGRAPHY TESTING

> Microstructure Examination of parent metal to confirm heat treatment condition.

> Microstructure Examination of welded samples.

> Grain size Measurement, Inclusion Rating

> Decarburizing Depth Measurement

> Case depth measurement for Carburizing/Nitriding/Induction Hardened parts

> Coating thickness measurement

> Macro examinations of welded sample

> Macro examinations of forged sample

> Macro examinations of Rolled sample

> Graphite size, type & distribution in cast Irons.

> Quantitative metallography to know the percentage of particular phase

> 0% ferrite in Duplex stainless steel

> Microstructure & Macrostructure Photography

> Replica Testing(In Situ-Metallography)

> Fractography

> Jominy End Quench Test

Civil Material Testing

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

Corrosion Testing

> Intergranular Corrosion Test as per ASTM A-262.

> Practice A

> Practice B

> Practice C

> Practice D

> Intergranular Corrosion Test as per ISO-3651.

> Practice A

> Practice B

> Practice C

> Practice D

> Hydrogen Induced Cracking Test (HIC)

> Sulphide Stress Corrosion Cracking test (SSCC)

> Chloride Stress Corrosion Cracking test (CSCC).

> Pitting Corrosion test (ASTM G-48 Method ‘A’)

> Crevice Corrosion test (ASTM G-48 Method ‘B’)

> Four Point Bend test as per NACE TM-0177.

> Corrosion test as per ASTM A-923 for detecting the detrimental phases.

> Salt Spray test

> We can offer all above mentioned tests under allthird party inspection agencies.